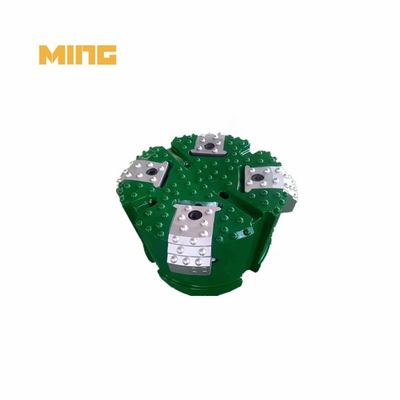

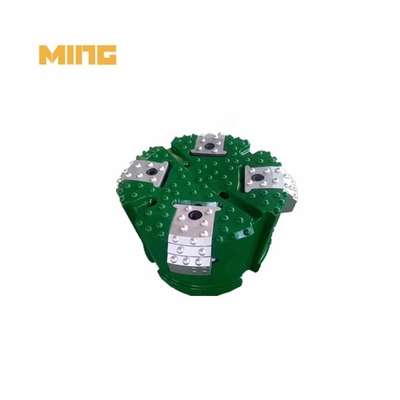

Product name: 432mm MNX365 Overburden Symmetric Casing Drilling System Bits With 4 Wings For Geothermal Drilling

Product category: symmetric casing drilling bit

Matched hammer: Hammer N120

Matched casing pipe OD: 365mm

One standout feature of the MNX Bit is its hardened surface treatment, providing a longer operating life and excellent anti-wear properties. This means that you can rely on this MNX bit for extended periods, reducing downtime and increasing productivity. Its hardened surface ensures durability, even in the harshest drilling conditions, making it a reliable choice for professionals in the industry.

MNX overburden symmetric casing drilling bit with 4 wing features:

1. High quality steels materials. Steel is from TIMKEN and Tungsten carbide are YK05, or T6 from Element Six in Germany

2. Kingdrilling DTH tools are forged by advanced electron-hydraulic forging hammer.

3. Advanced heat-treatment equipment: multipurpose furnace heat treatment.

4. Completed moulding (tooling ) departments with many molds available.

5. Professional R&D team,completed quality system.

Strict Quality-Check Systems.

MNX overburden symmetric casing drilling bit with 4 wings components:

Pilot bit+4PCS Slide blocks+casing shoe

MNX overburden symmetric casing drilling bit with 4 wing technical parameters:

| Model |

Hole dia (mm) |

Weight (KG) |

Closed dia (mm) |

Pilot dia (mm) |

Total length (mm) |

Case dia (OD*ID) |

Spline |

| MK-MNX365 |

432 |

350 |

365 |

381 |

1100 |

406*387 |

N120,N125 |

| MK-MNX410 |

478 |

450 |

412 |

430 |

1100 |

457*435 |

N125 |

| MK-MNX460 |

530 |

580 |

460 |

475 |

1100 |

508*483 |

N125,SD18 |

| MK-MNX510 |

580 |

760 |

509 |

527 |

1180 |

559*533 |

N180,SD18 |

| MK-MNX560 |

635 |

830 |

560 |

581 |

1180 |

610*584 |

N180,SD18 |

| MK-MNX610 |

695 |

960 |

600 |

630 |

1200 |

660*632 |

N240 |

| MK-MNX660 |

735 |

1180 |

656 |

681 |

1207 |

711*685 |

N240 |

| MK-MNX710 |

785 |

1400 |

710 |

730 |

1207 |

762*736 |

N240 |

| MK-MNX745 |

838 |

1600 |

745 |

776 |

1207 |

813*780 |

N240 |

Order Guide: Casing Tube OD + Casing Tube ID + Reamer Bit Diameter + Minimal Casing Shoe ID + Hammer Shank Style

Other size of MRS system is available upon customer's request

MNX overburden symmetric casing drilling bit with 4 wings Applications:

1. Water well drilling (consolidation of well heads, polluted groundwaters exclusion, ...)

2. Geothermal drilling

3. Civil engineering (anchorages, injections, road crossing, ...)

4. Mining exploration(pilot hole for core drilling, study of groundwaters

FAQ:

1. What is drill casing?

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream.

2. Why is overburden important?

In a petroleum system, the overburden rock overlies the source rock and contributes to its thermal maturation because of higher temperatures at greater depths. The age and thickness of the overburden rock determines the burial rate and thereby influences the heating rat.

3. Where do they put overburden?

The most common application for huge amounts of overburden generated by a surface mine is to remediate and reclaim the region where it was originally removed. Returning the sand, rock, and clay to their original locations helps to reestablish the soil's level, allowing plant life to return.

Product Manufacturing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!