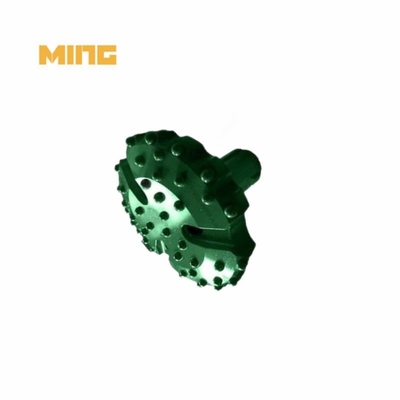

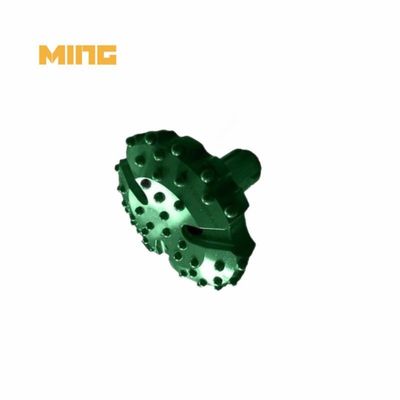

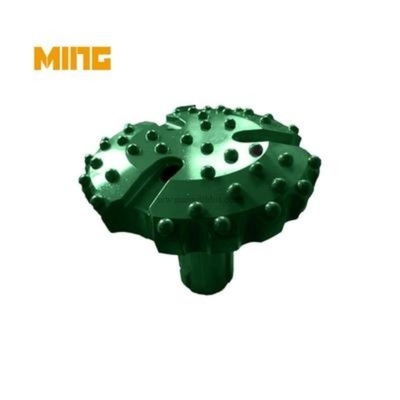

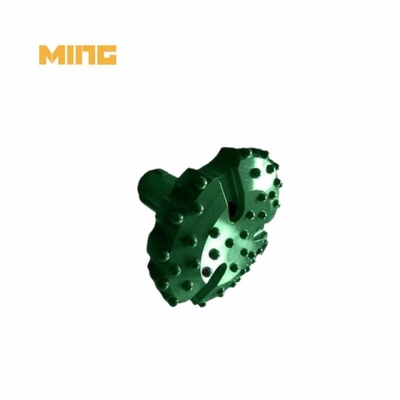

Product name: 140mm CIR110 Shank Down The Hole DTH Drill Button Bits For Construction Tunneling

Product category: DTH drill tools

Matched hammer: Hammer CIR110

Diameter: 140mm

KINGDRILLING DTH button bit description:

DTH (Down-The-Hole) drill bit is a cutting tool used in various industries for drilling boreholes into the ground. These drill bits are essential components of DTH drilling equipment, which is widely utilized in mining, construction, geothermal drilling, and water well drilling operations. In this comprehensive guide, we will delve into the intricacies of DTH drill bits, exploring their advantages, functions, features, and applications in detail.

DTH drill bits are specialized tools designed to penetrate hard rock formations efficiently and effectively. Unlike conventional drilling methods that rely on rotary drilling, DTH drilling involves a hammering action to break through rock formations. The DTH drill bit is attached to the end of the drill string and is powered by compressed air, providing the necessary force to create boreholes in challenging geological conditions.

KINGDRILLING Low air pressure DTH button bit shank technical parameters:

| Bit Dia.(mm) |

Bit Dia (Inch) |

Gauge Buttons |

Spline Num. |

Shank |

| 50 |

1 31/32 |

3×φ10 |

4 |

CIR50 |

| 55 |

2 5/32 |

3×φ10 |

4 |

CIR50 |

| 60 |

2 23/64 |

3×φ12 |

4 |

CIR60 |

| 65 |

2 9/16 |

4×φ12 |

4 |

CIR65 |

| 76 |

3 |

5×φ12 |

4 |

CIR70 |

| 90 |

3 35/64 |

6×φ14 |

6 |

CIR90 |

| 100 |

3 15/16 |

6×φ14 |

6 |

CIR90 |

| 105 |

4 1/8 |

6×φ14 |

6 |

CIR90 |

| 110 |

4 21/64 |

6×φ14 |

6 |

CIR90 |

| 120 |

4 23/32 |

6×φ14 |

6 |

CIR90 |

| 130 |

5 1/8 |

7×φ14 |

6 |

CIR90 |

| 110 |

4 21/64 |

6×φ14 |

6 |

CIR110 |

| 120 |

4 23/32 |

6×φ14 |

6 |

CIR110 |

| 125 |

4 59/64 |

7×φ14 |

6 |

CIR110 |

| 130 |

5 1/8 |

7×φ14 |

6 |

CIR110/CIR130 |

| 140 |

5 33/64 |

8×φ14 |

6 |

CIR110/CIR130 |

| 150 |

5 29/32 |

8×φ14 |

6 |

CIR110/CIR130 |

| 150 |

5 29/32 |

9×φ16 |

6 |

CIR150 |

| 165 |

6 1/2 |

9×φ16 |

6 |

CIR150 |

| 175 |

6 57/64 |

9×φ16 |

6 |

CIR150 |

| 185 |

7 9/32 |

9×φ16 |

6 |

CIR150 |

| 200 |

7 7/8 |

9×φ16 |

6 |

CIR150 |

| 175 |

6 57/64 |

9×φ16 |

6 |

CIR170 |

| 185 |

7 9/32 |

9×φ16 |

6 |

CIR170 |

| 200 |

7 7/8 |

9×φ16 |

6 |

CIR170 |

| 220 |

8 21/32 |

12×φ16 |

6 |

CIR170 |

| 250 |

9 27/32 |

12×φ16 |

6 |

CIR170 |

Order Guide: Shank+ Head diameter+Face design+Button shape

Advantages of DTH Drill Bits:

-

Efficiency: DTH drill bits are known for their high drilling efficiency, enabling rapid progress in challenging rock formations. The hammering action facilitates faster penetration rates compared to traditional drilling methods.

-

Versatility: These drill bits are versatile and can be used in various applications, including mining, construction, quarrying, and exploration drilling. They are suitable for both shallow and deep drilling operations.

-

Precision: DTH drill bits offer excellent precision and control, allowing operators to target specific rock formations accurately. This precision is essential in mining and exploration activities where the precise location of boreholes is crucial.

-

Cost-Effectiveness: While DTH drilling equipment may have higher upfront costs, the efficiency and speed of DTH drill bits often result in cost savings in the long run. The quicker drilling speed reduces operational downtime and labor costs.

-

Durable Construction: DTH drill bits are constructed from high-quality materials, such as tungsten carbide, to withstand the demands of heavy-duty drilling operations. This durability ensures a longer lifespan and reduces the frequency of replacements.

-

Suitable for Hard Rock Formations: DTH drill bits excel in drilling through hard rock formations, including granite, basalt, and quartzite. The hammering action generates sufficient force to break through these challenging materials.

Function of DTH Drill Bits:

The primary function of a DTH drill bit is to create boreholes in rock formations by utilizing a hammering action powered by compressed air. The drill bit is attached to the end of the drill string, which is connected to the DTH hammer. When the hammer strikes the drill bit, it applies force to the rock surface, creating fractures and enabling the bit to advance further into the formation.

The design of DTH drill bits plays a crucial role in their function. These bits typically feature tungsten carbide buttons or inserts that act as cutting edges. As the drill bit rotates and hammers against the rock surface, these inserts crush and break the rock, allowing the bit to progress deeper into the formation.

Features of DTH Drill Bits:

-

Tungsten Carbide Inserts: DTH drill bits are equipped with tungsten carbide inserts that provide excellent hardness and wear resistance. These inserts ensure that the drill bit maintains its cutting efficiency even in abrasive rock formations.

-

Different Face Designs: DTH drill bits come in various face designs, including convex, flat, and concave faces. Each face design is suited to different rock types and drilling conditions, allowing operators to choose the most appropriate bit for the job.

-

Multiple Nozzles: Many DTH drill bits are equipped with multiple nozzles strategically placed around the bit to provide efficient flushing of cuttings from the borehole. Proper flushing helps maintain drilling efficiency and prolongs the life of the bit.

-

High-Quality Steel Body: The body of a DTH drill bit is typically made from high-quality steel to ensure durability and resistance to the stresses of drilling operations. The steel body also helps dissipate heat generated during drilling, preventing premature wear.

-

Thread Connections: DTH drill bits feature thread connections that allow easy attachment to the drill string and DTH hammer. These connections are designed for quick assembly and disassembly, facilitating efficient drilling operations.

Applications of DTH Drill Bits:

-

Mining: DTH drill bits are widely used in mining operations for exploration drilling, production drilling, and blasting. They are essential for creating blast holes in hard rock formations to extract minerals efficiently.

-

Construction: In the construction industry, DTH drill bits are used for various applications, including foundation drilling, anchor bolt installation, and geotechnical investigations. These bits help create boreholes for building foundations and infrastructure projects.

-

Quarrying: DTH drill bits play a vital role in quarrying operations for extracting natural stone and aggregates. They are used to drill precise holes for explosive charges to break large rock formations into smaller pieces.

FAQ:

1. what is a button bit?

Tungsten carbide inserts rotate within the cones of button bits, also known as roller cones. Though producers still produce two cone and one cone bits, tricone, or three cone bits, are the most widely used.

2. How can one drill through large stones?

Drill for a minute while applying moderate pressure. Allow the drill to do the work; do not press the bit into the boulder. After taking the bit out of the hole, let it cool in the water pitcher. To cool the rock and remove dust, lightly mist it with water.

3. What about standard packaging?

A: If there is no special packing demand, we will take it as our normal packing. First in small carton, and then put in the bigger carton together to make sure goods completed.

4. How to check the product are the exact one you want?

A: If possible, please attach one reference picture to avoid any misunderstanding or any links from our website for a better understanding.

5. How to choose the suitable head face of the DTH drill bit?

Concave:

Suitable for all kinds of formation, especially for deep well drilling, perpendicularity of the hole is wonderful.

Convex:

Suitable for the formation of moderate hardness stratum, drilling efficiency is good, borehole perpendicularity is moderate.

Flat:

Suitable for special hard formation stratum, especially for fracture, crack spacing and complex formation drilling effect is very good, has the good perpendicularity of the borehole.

More information:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!