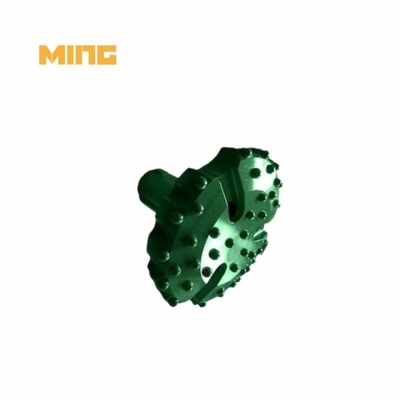

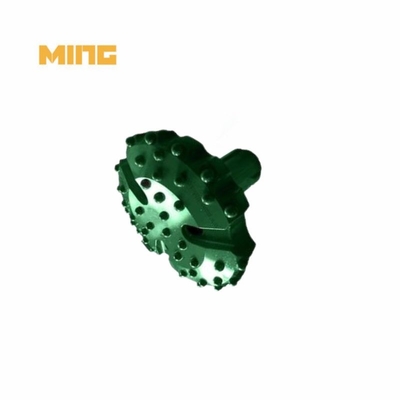

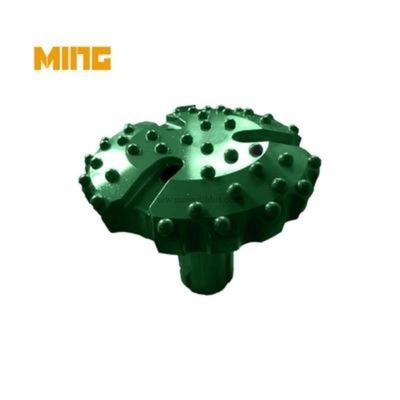

Product name: 150mm CIR110 Shank Down The Hole DTH Drill Hammer Button Bits For Underground Drilling

Product category: DTH drill tools

Matched hammer: Hammer CIR110

Diameter: 150mm

KINGDRILLING DTH button bit description:

Down-the-Hole (DTH) drill bits are essential tools used in the mining, construction, and oil and gas industries for drilling boreholes into the earth. These specialized drill bits are designed to deliver powerful and efficient drilling performance in a variety of challenging geological conditions. In this comprehensive guide, we will explore the advantages, functions, features, and applications of DTH drill bits in detail.

KINGDRILLING Low air pressure DTH button bit shank technical parameters:

| Bit Dia.(mm) |

Bit Dia (Inch) |

Gauge Buttons |

Spline Num. |

Shank |

| 50 |

1 31/32 |

3×φ10 |

4 |

CIR50 |

| 55 |

2 5/32 |

3×φ10 |

4 |

CIR50 |

| 60 |

2 23/64 |

3×φ12 |

4 |

CIR60 |

| 65 |

2 9/16 |

4×φ12 |

4 |

CIR65 |

| 76 |

3 |

5×φ12 |

4 |

CIR70 |

| 90 |

3 35/64 |

6×φ14 |

6 |

CIR90 |

| 100 |

3 15/16 |

6×φ14 |

6 |

CIR90 |

| 105 |

4 1/8 |

6×φ14 |

6 |

CIR90 |

| 110 |

4 21/64 |

6×φ14 |

6 |

CIR90 |

| 120 |

4 23/32 |

6×φ14 |

6 |

CIR90 |

| 130 |

5 1/8 |

7×φ14 |

6 |

CIR90 |

| 110 |

4 21/64 |

6×φ14 |

6 |

CIR110 |

| 120 |

4 23/32 |

6×φ14 |

6 |

CIR110 |

| 125 |

4 59/64 |

7×φ14 |

6 |

CIR110 |

| 130 |

5 1/8 |

7×φ14 |

6 |

CIR110/CIR130 |

| 140 |

5 33/64 |

8×φ14 |

6 |

CIR110/CIR130 |

| 150 |

5 29/32 |

8×φ14 |

6 |

CIR110/CIR130 |

| 150 |

5 29/32 |

9×φ16 |

6 |

CIR150 |

| 165 |

6 1/2 |

9×φ16 |

6 |

CIR150 |

| 175 |

6 57/64 |

9×φ16 |

6 |

CIR150 |

| 185 |

7 9/32 |

9×φ16 |

6 |

CIR150 |

| 200 |

7 7/8 |

9×φ16 |

6 |

CIR150 |

| 175 |

6 57/64 |

9×φ16 |

6 |

CIR170 |

| 185 |

7 9/32 |

9×φ16 |

6 |

CIR170 |

| 200 |

7 7/8 |

9×φ16 |

6 |

CIR170 |

| 220 |

8 21/32 |

12×φ16 |

6 |

CIR170 |

| 250 |

9 27/32 |

12×φ16 |

6 |

CIR170 |

Order Guide: Shank+ Head diameter+Face design+Button shape

Advantages of DTH Drill Bits:

-

Efficiency: DTH drill bits are known for their high drilling efficiency, allowing for faster penetration rates compared to traditional drilling methods. This efficiency is crucial in reducing operational costs and maximizing productivity on drilling sites.

-

Versatility: DTH drill bits are versatile tools that can be used in various applications, including hard rock drilling, exploration drilling, water well drilling, and foundation drilling. Their adaptability makes them suitable for a wide range of drilling projects.

-

Precision: These drill bits offer exceptional precision and accuracy in drilling operations, ensuring that boreholes are drilled to the desired depth and angle with minimal deviation. This precision is essential for maintaining the integrity of the borehole and achieving project objectives.

-

Durability: DTH drill bits are constructed from high-quality materials, such as tungsten carbide and high-strength steel, to withstand the rigors of drilling in challenging rock formations. Their durability ensures long-lasting performance and reduces the frequency of bit replacements.

-

Cost-Effectiveness: While initial costs may be higher than conventional drilling tools, the long-term cost-effectiveness of DTH drill bits lies in their durability, efficiency, and reduced downtime. These factors contribute to overall cost savings in drilling operations.

-

High Penetration Rates: DTH drill bits are capable of achieving high penetration rates in various rock formations, including hard and abrasive formations. This capability allows for rapid drilling progress and increased operational efficiency on drilling sites.

Function of DTH Drill Bits:

DTH drill bits function by using compressed air to drive the drilling process. The drill bit is connected to the bottom of the drill string, which is then attached to the drilling rig. When the drill rig activates the air compressor, high-pressure air is forced down the drill string to the drill bit.

Upon reaching the drill bit, the compressed air exits through nozzles located on the face of the bit, creating a high-velocity airflow that carries rock cuttings up the annular space between the drill string and the borehole wall. Simultaneously, the impact of the airflow on the drill bit face fractures the rock, allowing the bit to advance deeper into the formation.

The design of DTH drill bits includes features such as tungsten carbide buttons or teeth arranged in a specific pattern on the bit face to maximize drilling efficiency and maintain stability during operation. Additionally, the shape and configuration of the bit are optimized for specific drilling conditions to achieve the desired drilling performance.

Features of DTH Drill Bits:

-

Tungsten Carbide Inserts: DTH drill bits are equipped with tungsten carbide inserts that provide excellent wear resistance and cutting performance in hard rock formations. These inserts are strategically placed on the bit face to ensure efficient rock penetration.

-

Bit Design: The design of DTH drill bits varies based on the intended application, rock formation, and drilling conditions. Common designs include convex, flat, and concave faces, each offering specific advantages in terms of cutting efficiency and stability.

-

Bit Size and Diameter: DTH drill bits are available in a range of sizes and diameters to accommodate different borehole requirements. Larger diameter bits are used for wide-diameter drilling, such as foundation drilling, while smaller bits are suitable for exploration and water well drilling.

-

Bit Shank Configuration: The shank of a DTH drill bit is designed to connect securely to the drill string and transfer impact energy from the hammer to the bit face. Shank configurations may include spline, API, or QL designs, depending on the type of hammer used and drilling rig specifications.

-

Bit Face Patterns: Depending on the rock formation being drilled, DTH drill bits feature different patterns of tungsten carbide inserts on the bit face. Common patterns include cross, dome, and ballistic designs, each optimized for specific drilling conditions to maximize cutting efficiency.

Applications of DTH Drill Bits:

-

Mining: DTH drill bits are widely used in the mining industry for drilling blast holes, production holes, and exploration holes in hard rock formations. These drill bits are essential for mineral exploration, quarrying, and open-pit mining operations.

-

Construction: In the construction sector, DTH drill bits are utilized for foundation drilling, anchoring, and geotechnical drilling applications. Their high penetration rates and precision drilling capabilities make them ideal for creating boreholes in various soil and rock types.

FAQ:

1. what is a button bit?

Tungsten carbide inserts rotate within the cones of button bits, also known as roller cones. Though producers still produce two cone and one cone bits, tricone, or three cone bits, are the most widely used.

2. How can one drill through large stones?

Drill for a minute while applying moderate pressure. Allow the drill to do the work; do not press the bit into the boulder. After taking the bit out of the hole, let it cool in the water pitcher. To cool the rock and remove dust, lightly mist it with water.

3. What about standard packaging?

A: If there is no special packing demand, we will take it as our normal packing. First in small carton, and then put in the bigger carton together to make sure goods completed.

4. How to check the product are the exact one you want?

A: If possible, please attach one reference picture to avoid any misunderstanding or any links from our website for a better understanding.

5. How to choose the suitable head face of the DTH drill bit?

Concave:

Suitable for all kinds of formation, especially for deep well drilling, perpendicularity of the hole is wonderful.

Convex:

Suitable for the formation of moderate hardness stratum, drilling efficiency is good, borehole perpendicularity is moderate.

Flat:

Suitable for special hard formation stratum, especially for fracture, crack spacing and complex formation drilling effect is very good, has the good perpendicularity of the borehole.

More information:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!