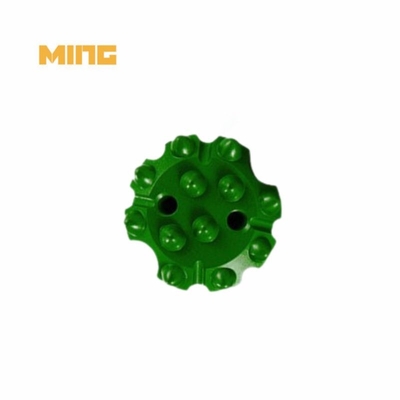

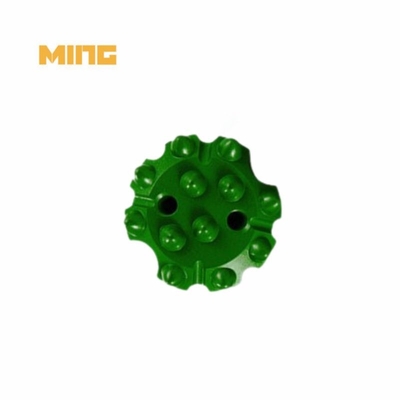

Product name: 38mm Diameter Down The Hole R25 Thread Button Drill Bit For Construction Geothermal Drilling

Product category: DTH thread button drill bit

Matched connection: R25

Diameter: 38mm

Matched: shank rod, and MM and MF Hex drifter rod

KINGDRILLING DTH thread button bit description:

Thread drill button bits are crucial components in the world of drilling operations, favored for their efficiency and precision. These bits are designed to bore through tough materials with ease, providing a reliable solution for various industries ranging from mining to construction. In this comprehensive guide, we will delve into the intricacies of thread drill button bits, exploring their advantages, functions, features, and applications in detail.

KINGDRILLING DTH thread button bit technical parameters:

|

Model

|

Bit Dia.(mm)

|

Thread

|

NO. X Button Dia.

|

NO.Flushing Holes(PCS)

|

Weight(KG)

|

|

Gauge

|

Front

|

Side

|

Front

|

|

MTN33F5R22

|

33

|

R22

|

5×7

|

2×7

|

2

|

1

|

0.4

|

|

MTN35F5R25

|

35

|

R25

|

5×8

|

2×7

|

2

|

1

|

0.4

|

|

MTN38F5R25

|

38

|

R25

|

5×8

|

2×7

|

1

|

2

|

0.5

|

|

MTN41F5R25

|

41

|

R25

|

5×9

|

2×8

|

1

|

2

|

0.55

|

|

MTN41F5R28

|

41

|

R28

|

5×9

|

2×8

|

1

|

2

|

0.65

|

|

MTN41F4R32

|

41

|

R32

|

4×9

|

2×8

|

2

|

1

|

0.65

|

|

MTN41F5R32

|

41

|

R32

|

5×9

|

2×8

|

2

|

1

|

0.65

|

|

MTN43F4R28

|

43

|

R28

|

4×9

|

2×9

|

1

|

1

|

0.67

|

|

MTN43FR528

|

43

|

R28

|

5×9

|

2×8

|

2

|

1

|

0.67

|

|

MTN43F4R32

|

43

|

R32

|

4×9

|

2×9

|

2

|

1

|

0.67

|

|

MTN43F5R32

|

43

|

R32

|

5×10

|

2×9

|

2

|

1

|

0.67

|

|

MTN43F6R32

|

43

|

R32

|

6×9

|

2×8

|

1

|

2

|

0.67

|

|

MTN45F4R28

|

45

|

R28

|

4×10

|

2×9

|

1

|

1

|

0.8

|

|

MTN45F5R28

|

45

|

R28

|

5×9

|

2×9

|

2

|

1

|

0.8

|

|

MTN45F6R28

|

45

|

R28

|

6×9

|

3×8

|

3

|

1

|

0.8

|

|

MTN45F5R32

|

45

|

R32

|

5×11

|

2×9

|

2

|

1

|

0.8

|

|

MTN45F6R32

|

45

|

R32

|

6×9

|

3×8

|

1

|

3

|

0.8

|

|

MTN48F5R32

|

48

|

R32

|

5×11

|

2×9

|

2

|

1

|

0.9

|

|

MTN48F6R32

|

48

|

R32

|

6×9

|

3×8

|

1

|

3

|

0.9

|

|

MTN51F5R32

|

51

|

R32

|

5×11

|

2×10

|

2

|

1

|

1.1

|

|

MTN51F6R32

|

51

|

R32

|

6×10

|

3×9

|

1

|

3

|

1.1

|

|

MTN57F6R32

|

57

|

R32

|

6×11

|

3×10

|

-

|

3

|

1.3

|

|

MTN64F6R32

|

64

|

R32

|

6×11

|

3×11

|

2

|

1

|

1.6

|

|

MTN64F8R32

|

64

|

R32

|

8×10

|

4×10

|

2

|

2

|

1.6

|

|

MTN64F6R38

|

64

|

R38

|

6×12

|

3×11

|

2

|

1

|

1.6

|

|

MTN76F6R32

|

76

|

R32

|

6×12

|

6×11

|

1

|

2

|

2.7

|

|

MTN76F8R32

|

76

|

R32

|

8×11

|

4×11

|

2

|

2

|

2.3

|

|

MTN76F8R38

|

76

|

R38

|

8×12

|

4×11

|

2

|

2

|

1.9

|

|

MTN89F7R32

|

89

|

R32

|

7×12

|

6×11

|

-

|

3

|

3

|

|

MTN89F8R32

|

89

|

R32

|

8×12

|

5×12

|

2

|

2

|

2.9

|

|

MTN89F8R38

|

89

|

R38

|

8×12

|

5×12

|

2

|

2

|

3.3

|

|

MTN102F14R32

|

102

|

R32

|

14×12

|

1×11

|

2

|

3

|

3.5

|

Order Guide: Order Guide: Diameter + Thread + Skirt Shape + Face Design + Insert Shape

Advantages of Thread Drill Button Bits:

-

Efficiency: Thread drill button bits are known for their high drilling efficiency, allowing operators to complete tasks quickly and effectively. The specialized design of these bits enables them to penetrate hard surfaces with minimal effort, reducing downtime and increasing productivity.

-

Precision: These bits offer exceptional precision during drilling operations, ensuring accurate hole formation. The buttons on the bit's surface are strategically placed to deliver precise impacts, resulting in clean and consistent boreholes.

-

Durability: Thread drill button bits are built to withstand harsh drilling conditions, offering exceptional durability and longevity. The materials used in their construction are carefully selected to enhance resistance to wear and tear, extending the lifespan of the bits.

-

Versatility: These bits are versatile tools that can be used across a wide range of applications, making them valuable assets for various industries. Whether drilling through rock formations, concrete, or other challenging materials, thread drill button bits can adapt to different environments with ease.

-

Cost-Effectiveness: Due to their efficiency and durability, thread drill button bits offer a cost-effective solution for drilling operations. Their long lifespan and consistent performance help reduce maintenance costs and downtime, ultimately leading to savings for businesses.

Function of Thread Drill Button Bits:

Thread drill button bits function by utilizing a combination of impact and rotation to bore through hard surfaces. The buttons on the bit's face are made of tough materials like tungsten carbide, which can withstand high levels of impact and abrasion. When the bit rotates, these buttons strike the rock surface, breaking it apart and creating a hole.

The thread design on these bits allows for easy installation and removal from the drilling equipment, enabling quick transitions between different types of bits. This feature enhances operational efficiency and minimizes downtime during drilling operations.

Thread drill button bits come in various sizes and configurations to accommodate different drilling requirements. Operators can select the appropriate bit based on factors such as rock hardness, drilling depth, and desired hole diameter, ensuring optimal performance for each specific application.

Features of Thread Drill Button Bits:

-

Button Configuration: Thread drill button bits feature an array of buttons arranged in a precise pattern on the bit's face. These buttons come in different shapes and sizes to deliver varying levels of impact and penetration, allowing for customized drilling performance.

-

Body Design: The body of thread drill button bits is typically made of high-strength steel to withstand the rigors of drilling operations. The design of the body is optimized for durability and efficient energy transfer from the drill rig to the rock surface.

-

Thread Type: Thread drill button bits are equipped with threads that match the corresponding drill rods or couplings. This thread design ensures a secure connection between the bit and the drilling equipment, preventing slippage or misalignment during operation.

-

Flushing Holes: Some thread drill button bits feature flushing holes that allow for the passage of drilling fluids to cool the bit and carry away debris. This feature helps maintain the bit's performance by preventing overheating and ensuring clean drilling operations.

-

Compatibility: Thread drill button bits are designed to be compatible with various drilling rigs and equipment, providing versatility for different applications. Operators can easily switch between different types of thread drill button bits to suit specific drilling requirements.

Applications of Thread Drill Button Bits:

-

Mining: Thread drill button bits are widely used in mining operations for extracting minerals and ores from underground deposits. These bits are essential for creating blast holes, ventilation shafts, and exploration boreholes in challenging geological conditions.

-

Construction: In the construction industry, thread drill button bits are utilized for tasks such as foundation drilling, tunneling, and rock anchoring. These bits play a crucial role in creating stable and precise holes for building foundations, bridges, and other structures.

-

Quarrying: Quarrying operations rely on thread drill button bits to extract stone blocks and aggregates from quarries. These bits are instrumental in shaping and sizing rocks for use in construction, landscaping, and other applications.

-

Geothermal Drilling: Thread drill button bits are used in geothermal drilling projects to access underground heat sources for energy production. These bits help create boreholes for installing geothermal heat exchange systems efficiently.

-

Water Well Drilling: Thread drill button bits are employed in water well drilling to penetrate various rock formations and reach aquifers. These bits enable the construction of reliable and efficient water supply wells for agricultural, industrial, and residential purposes.

FAQ:

1. How to order the products?

A: Please send the inquiry with detail item description or with Model number.

2. Can I expect a quality products?

A: Yes. mature production technology ensuring the quality satisfy international request.

3. How to control quality?

A: We have our own experienced QC team,there will be strict inspection and testing for each order before shipping out.

4. Competitive price:

A: KINGDRILLING factory can supply you the lowest price due to direct sale to customers without distributor.

5. What is the Application?

Mining, Quarrying, Tunneling, Construction, Geological Exploration, Water-well Drilling, Oilfield & Gas Industries.

6. Product feature

Kingdrilling DTH tools are forged by advanced electron-hydraulic forging hammer, and harness process is managed by multipurpose furnace heat treatment.

More information:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!