Product Description:

The Overburden Drilling System is a highly advanced and efficient drilling solution designed specifically for the demanding requirements of mining, construction, and water well drilling applications. This robust system is engineered to perform precise hole drilling operations, making it an indispensable tool in various industrial sectors where surface overburden removal and subsurface exploration are critical. Whether deployed in mining sites, large-scale construction projects, or water well installations, the Overburden Drilling Rig ensures superior performance, reliability, and operational efficiency.

Constructed using high-quality steel and carbide alloy materials, the Overburden Drilling Rig combines strength, durability, and wear resistance to withstand the harshest working environments. The steel framework provides the structural integrity necessary for heavy-duty drilling tasks, while the carbide alloy components enhance cutting efficiency and longevity. This combination of materials ensures that the equipment maintains optimal functionality over extended periods, reducing downtime and maintenance costs.

The Overburden Drilling System is powered by either a diesel engine or an electric motor, offering versatile power source options to suit different operational contexts and environmental considerations. The diesel engine variant is ideal for remote locations where electric power supply may be limited, delivering robust power and mobility. On the other hand, the electric motor version caters to sites with reliable electricity access, providing quieter operation and reduced emissions, aligning with modern environmental standards.

As a type of specialized drilling equipment, the Overburden Drilling Rig is designed to efficiently penetrate surface layers and overburden materials, enabling access to underlying rock formations or water tables. Its advanced drilling mechanisms and adaptable configurations allow it to handle a wide range of soil and rock types, ensuring consistent drilling accuracy and speed. This versatility makes the surface overburden drilling device an essential asset in exploration and extraction activities.

In mining applications, the Overburden Drilling Rig plays a crucial role in removing the overlying soil and rock layers that cover mineral deposits. By facilitating rapid and precise hole drilling, it aids in blasting preparations and resource extraction, thereby enhancing overall mining productivity. Similarly, in construction projects, the system is utilized for foundation drilling, soil testing, and other preparatory tasks that require reliable and efficient drilling performance.

Water well drilling is another significant application area for the Overburden Drilling System. Its capability to drill through varying strata makes it suitable for accessing groundwater resources in both urban and rural settings. The system’s adaptability to different drilling depths and conditions ensures the successful establishment of wells, contributing to sustainable water supply solutions.

Overall, the Overburden Drilling Rig embodies cutting-edge engineering and practical design tailored to meet the needs of mining, construction, and water well drilling industries. Its combination of durable materials, flexible power options, and precise drilling capabilities positions it as a leading surface overburden drilling device in the market. For organizations seeking reliable, efficient, and versatile drilling equipment, this system represents an excellent investment that enhances operational effectiveness and project outcomes.

Features:

-

Product Name: Overburden Drilling System

-

Type: Surface Overburden Drilling Device

-

Procession: Forging, Machining Process for enhanced durability

-

Model Shank: CIR Shank ensuring compatibility and performance

-

Mobility: Available in Crawler Mounted and Wheeled configurations

-

Drill Speed: Variable speed from 0 to 100 RPM for precision control

-

Power Source: Options include Diesel Engine and Electric Motor

-

Designed as an Overburden Drilling System Unit for efficient operation

-

Robust build suitable for demanding surface drilling applications

-

Reliable Overburden Drilling System Unit for consistent performance

Technical Parameters:

|

Power Source

|

Diesel Engine / Electric Motor

|

|

Type

|

Drilling Equipment

|

|

Material

|

High Manganese Steel, Carbide

|

|

Model Shank

|

CIR Shank

|

|

Drill Speed

|

0-100 Rpm

|

|

Usage

|

Hole Drilling, Mining & Construction & Water Well Drilling

|

|

Materials

|

Steel, Carbide Alloy

|

|

Hammer Type

|

Overburden Drilling System

|

|

Matched Hammer

|

Hammer DHD360

|

|

Application

|

Mining And Construction

|

Applications:

The MING Overburden Drilling System Unit is a highly efficient and reliable solution designed for various industrial and construction applications. Manufactured in China and certified with ISO9001, this drilling equipment ensures superior quality and performance. With a minimum order quantity of just 1PC and a price range between 999-99999 USD per unit, the MING Overburden Drilling System caters to both small-scale projects and large industrial operations.

This Overburden Drilling System Unit is constructed from high manganese steel and carbide alloy materials, combining strength and durability to withstand the toughest drilling environments. The system incorporates advanced forging and machining processes, resulting in a robust Overburden Drilling Machine that delivers consistent drilling speed ranging from 0 to 100 RPM. This precise control over drilling speed enhances operational efficiency and accuracy across different terrains and material types.

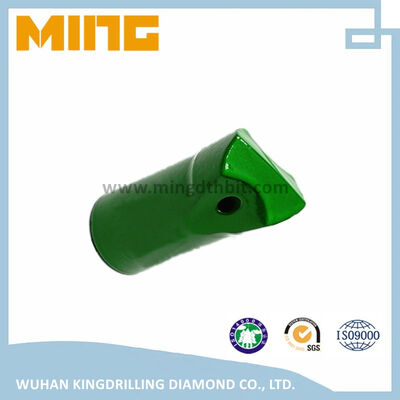

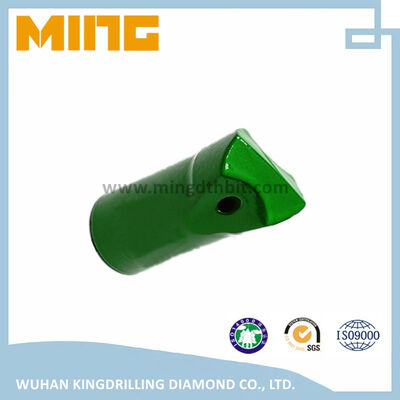

The Overburden Drilling bit, a core component of the system, is engineered to penetrate hard overburden layers effectively, making it ideal for mining, geological exploration, and construction projects where removing surface layers is critical. Packaged securely in a wooden case, the Overburden Drilling System Unit ensures safe transportation and storage, with delivery times ranging from 3 to 5 weeks depending on order specifics.

MING offers flexible payment terms including T/T, D/P, and Western Union, facilitating smooth transactions for clients worldwide. With a supply ability of 2000PCS per month, MING can meet high demand promptly without compromising on quality. This makes the Overburden Drilling Machine suitable for diverse application occasions such as mineral extraction, environmental site assessments, foundation drilling, and infrastructure development.

In summary, the MING Overburden Drilling System Unit is an indispensable tool for professionals requiring reliable drilling equipment capable of handling complex overburden removal tasks. Its high-quality Overburden Drilling bit and machine components, combined with rigorous manufacturing standards, make it a preferred choice in industries where precision, durability, and efficiency are paramount.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!